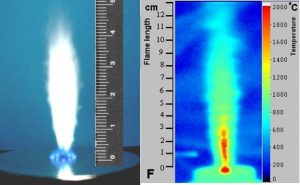

Flame pyrolysis for the production of nanostructured materials

The flame pyrolysis (FP) technique allows the one pot production of nanostructured single or mixed oxides. The materials are also characterised by higher thermal resistance with respect to conventional preparation techniques.

Up to now many different families of catalysts have been prepared for widely different applications (catalytic combustion, steam reforming, Fisher Tropsch, oxidative dehydrogenation of paraffins to olefins, photocatalysis…).

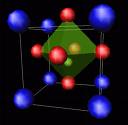

Characterisation of nanostructured materials

The deep characterisation of materials is fundamental to interpret their behaviour and to optimise them.

Some of the available tools in our labs are listed here:

- TPD-TPO-TPR, continuous or pulsed

- N2 adsorption/desorption (including tool for micropores) (Micromeritics, ASAP 2020)

- Chemisorption and adsorption of vapours (Micromeritics, ASAP 2020)

- FT-IR, equipped with UHV line and gas/vapour dosing system and ATR tool

- XRD (Phillips, PW 3020)

- Ionic Chromatography (Metrohm, IC883)

- UV-Vis spectroscopy (Perkin Elmer)

The group can access the following facilities:

- SEM (Leica, LEO 1430) with EDS and BS

- TEM

- TGA-DSC

- UV-Vis (Beckman, DU640) with integration sphere

- EPR

Furthermore, interdepartmental facilities are accessible as follows SmartMatLab, Advanced microscopy lab, Great equipments centre.

Active research topics:

flame pyrolysis synthesis of oxide nanomaterials, also for catalytic and photocatalytic applications;

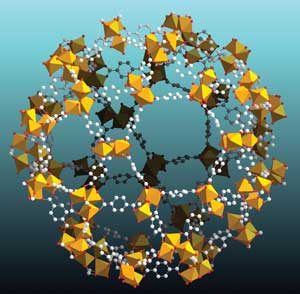

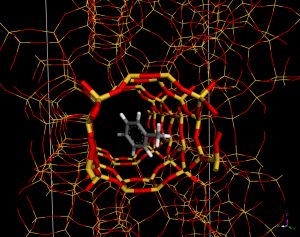

microporous materials for H2 storage

development of getters for adsorption of small molecules